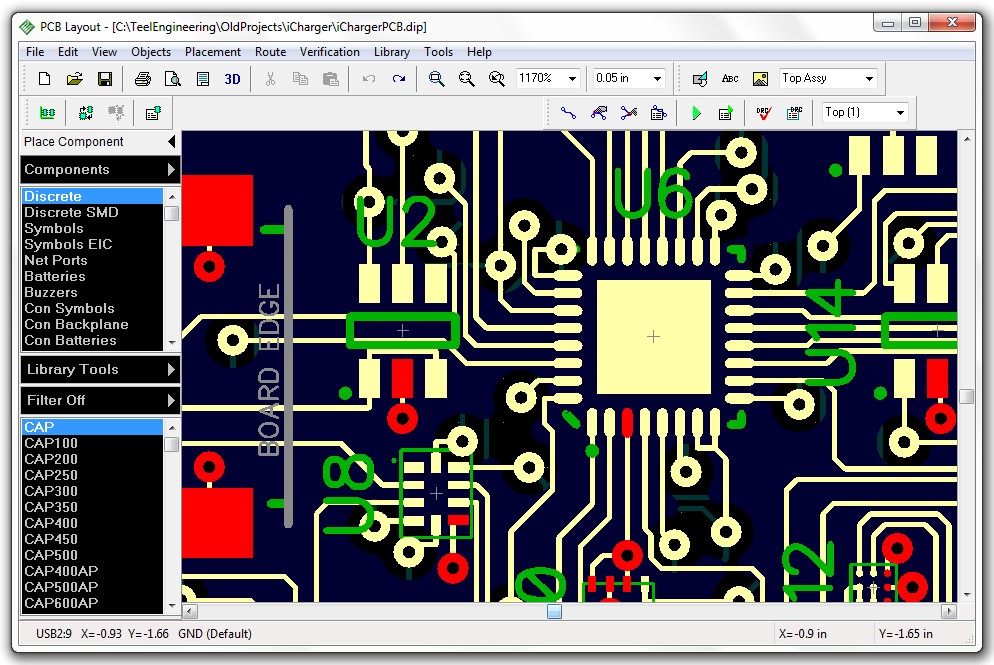

We are going to try importing the step file into Blender overnight (or maybe we have to convert it to a mesh file first), decimate the file, and then try importing the result into SolidWorks.

Or sometimes, we need to align a flex board with an FPC connector. It's common for us to need to know where the component body ends so that we can place a mould section next to it, sitting above its legs. Since our moulds need to wrap tightly around components, this solution doesn't work. the bodies are just bounding boxes (as intended by the file format). However, the component bodies get expanded to cover the legs and whatever other details. These take a very long time to import into SolidWorks, but once there, we can save the files as a SolidWorks part which is the most optimised solution that we've seen for PC performance. We also tried using Altium's IDF Board exporter with several different file formats. Jokes aside though, these files are unworkable.

It's funny how the number of duplicate IC models seems to correlate to how much precious board space they take away 😂. Parasolid works much better than Step, but both make our mechanical engineer's very sad. Step and Parasolid files on a board this size destroy SolidWorks.

0 kommentar(er)

0 kommentar(er)